Wood veneer plays a critical role in modern furniture and cabinetry design. For interior designers and contractors, understanding the different types of wood veneer is essential when balancing aesthetics, durability, budget, and project requirements. Veneer allows designers to achieve the look of solid wood while offering greater stability, flexibility, and cost control.

This guide explores the most common types of wood veneer used in furniture and cabinetry, how they are made, their visual characteristics, and where each performs best in real-world projects.

What Is Wood Veneer?

Wood veneer is a thin slice of natural wood, typically less than 3 mm thick, applied to a substrate such as plywood, MDF, or particleboard. Unlike solid wood, veneer minimizes warping and cracking while preserving the authentic grain, color, and texture of real wood.

From luxury kitchens to commercial interiors, veneer remains a preferred material for high-end yet practical design solutions.

Why Veneer Matters in Furniture and Cabinetry

Before diving into the types of wood veneer, it’s important to understand why professionals rely on veneer instead of solid lumber:

- Greater dimensional stability in changing humidity

- More efficient use of rare or expensive wood species

- Consistent grain matching across large surfaces

- Lower material cost without sacrificing appearance

- Compatibility with modern manufacturing techniques

For cabinetry, wardrobes, and doors, veneer provides a refined finish that performs well over time.

Types of Wood Veneer by Manufacturing Method

1. Rotary Cut Veneer

Rotary cut veneer is produced by mounting a log on a lathe and rotating it against a blade, peeling the wood in a continuous sheet.

Characteristics:

- Broad, open grain patterns

- High yield and minimal waste

- Economical and widely available

Best Uses:

- Large cabinet panels

- Commercial furniture

- Projects with tight budgets

While rotary cut veneer lacks the refined grain of other cuts, it works well for contemporary or utility-focused interiors.

2. Plain Sliced (Flat Cut) Veneer

Plain sliced veneer is created by slicing the log parallel to its growth rings. This produces the classic “cathedral” grain pattern many clients associate with traditional wood furniture.

Characteristics:

- Strong grain variation

- Warm, natural appearance

- Most common veneer cut

Best Uses:

- Kitchen cabinets

- Wardrobes

- Residential furniture

This is one of the most popular types of wood veneer for traditional and transitional designs.

3. Quarter Sliced Veneer

Quarter-sliced veneer is cut from logs that are first quartered lengthwise, then sliced at right angles to the growth rings.

Characteristics:

- Straight, tight grain

- More uniform appearance

- Greater dimensional stability

Best Uses:

- High-end cabinetry

- Office furniture

- Interior doors

Quarter-sliced veneer is often chosen when designers want a clean, structured look with minimal grain variation.

4. Rift Cut Veneer

Rift cut veneer is similar to quarter slicing but is cut at a slight angle to produce very straight, consistent grain without ray flecks.

Characteristics:

- Linear, modern grain

- Minimal visual movement

- Limited availability and higher cost

Best Uses:

- Contemporary furniture

- Luxury cabinetry

- Minimalist interiors

For designers working on modern or upscale projects, rift cut veneer offers a refined, architectural finish.

Types of Wood Veneer by Wood Species

Beyond cut methods, the wood species itself significantly impacts performance and appearance. Below are common veneer species used in furniture and cabinetry.

1. Oak Veneer

Oak veneer is known for its durability and pronounced grain.

Advantages:

- Strong and wear-resistant

- Available in red and white oak

- Accepts stains well

Widely used in cabinets, doors, and commercial interiors.

2. Walnut Veneer

Walnut veneer offers rich color and elegant grain, making it a favorite in premium projects.

Advantages:

- Dark, warm tones

- Smooth grain pattern

- Ideal for statement pieces

Common in luxury kitchens, wall panels, and custom furniture.

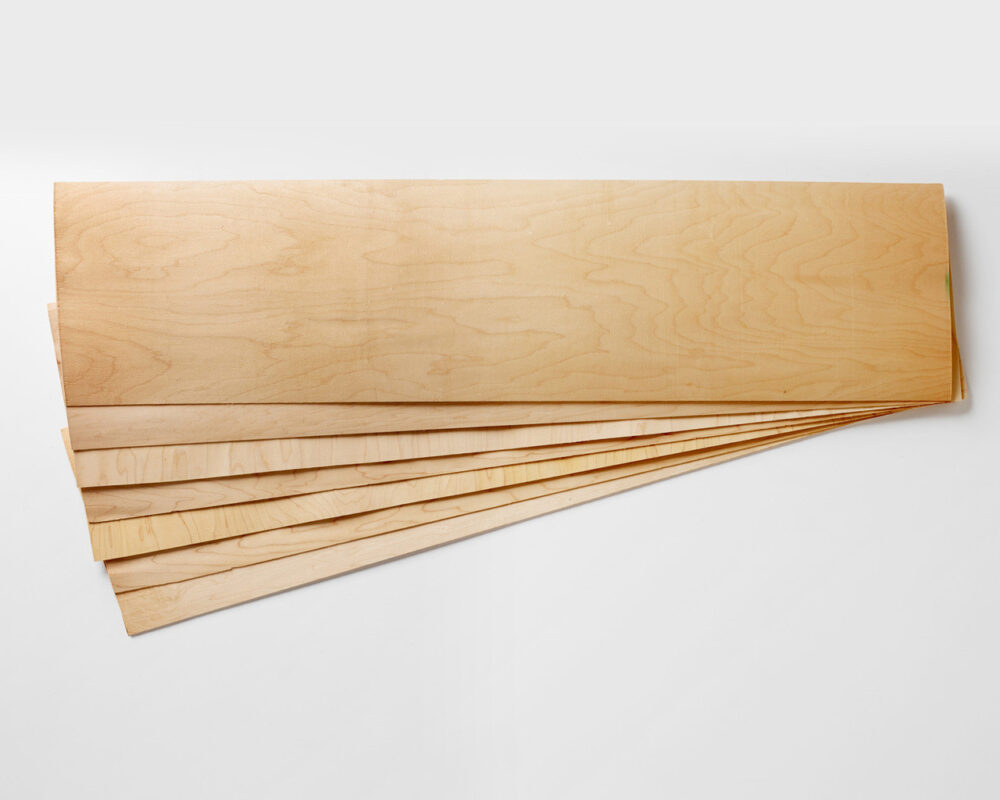

3. Maple Veneer

Maple veneer provides a clean and subtle appearance.

Advantages:

- Light color

- Fine, uniform grain

- Contemporary appeal

Best for modern cabinetry, wardrobes, and Scandinavian-style interiors.

4. Cherry Veneer

Cherry veneer darkens over time, adding character and depth.

Advantages:

- Smooth texture

- Warm reddish tones

- Ages beautifully

Often specified for classic furniture and traditional cabinetry.

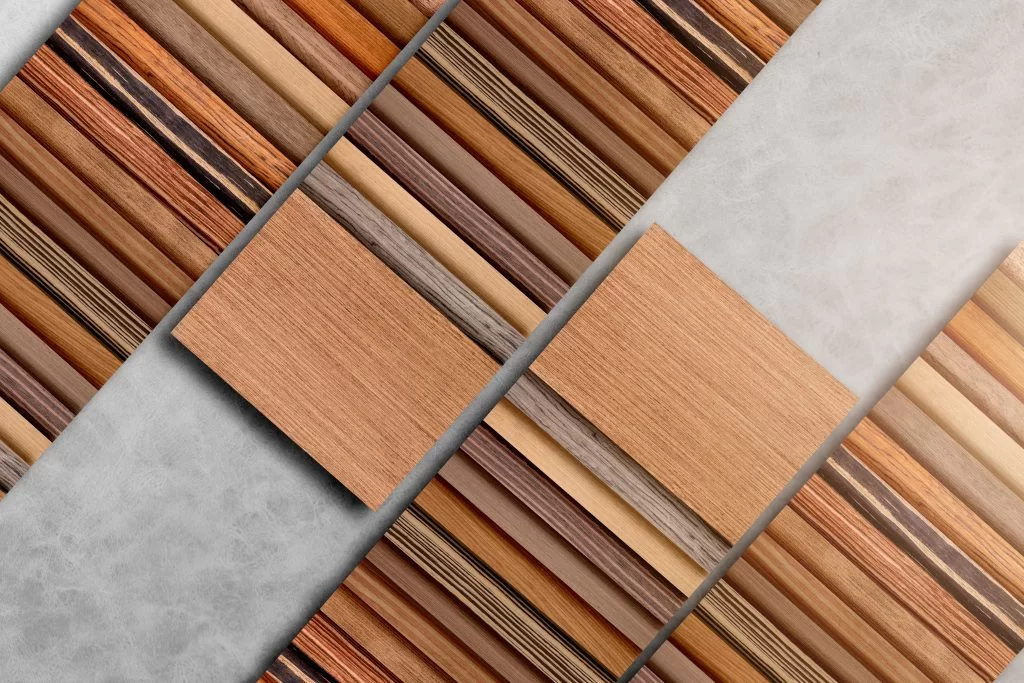

5. Exotic Wood Veneers

Exotic veneers such as teak, ebony, rosewood, and zebrawood offer unique patterns and colors.

Advantages:

- Distinctive visual impact

- Ideal for accent surfaces

- Adds exclusivity to projects

These veneers are commonly used for feature panels, luxury doors, and custom-designed furniture.

Natural Veneer vs Engineered Veneer

Another important distinction among types of wood veneer is whether they are natural or engineered.

1. Natural Wood Veneer

Made directly from logs, natural veneer preserves the authentic grain and variation of real wood.

Pros:

- Genuine appearance

- Unique patterns

- Premium feel

Cons:

- Limited consistency

- Higher cost for rare species

2. Engineered (Reconstituted) Veneer

Engineered veneer is manufactured from fast-growing wood species that are dyed and layered to mimic natural wood grain.

Pros:

- Excellent consistency

- Sustainable

- Cost-effective for large projects

Cons:

- Less natural variation

- Slightly more uniform look

For large-scale cabinetry or multi-unit projects, engineered veneer offers reliability and efficiency.

Conclusion

Selecting quality veneer is only part of the equation. Precision manufacturing, advanced finishing, and consistent quality control are just as critical.

OPPOLIA is a well-known door manufacturer providing whole-house solutions, including custom cabinets, interior doors, wardrobes, bathroom vanities, aluminium windows, and furniture. With extensive experience in veneer applications and large-scale projects, OPPOLIA supports designers and contractors from concept to completion.

If you are looking for a reliable project partner, OPPOLIA is the best choice.

Download the OPPOLIA kitchen catalog and get more information to explore premium veneer options and integrated whole-house solutions tailored to your projects.